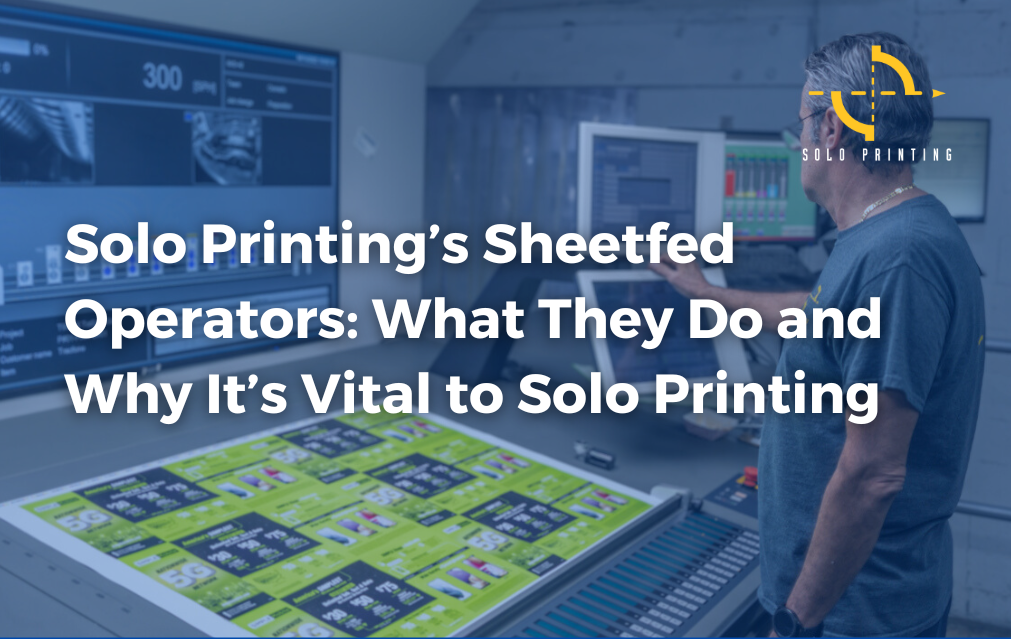

At Solo Printing, our success hinges on the expertise and dedication of our amazing team! Among all of our essential professionals, we have our sheetfed operators, who play a crucial role in ensuring the quality and efficiency of our printing processes. And, this August, we are excited to shine the spotlight on one of our outstanding employees, Conrado Lara, a testament to the skill and dedication that defines our Sheetfed Operating team.

What is Sheetfed Printing?

Sheetfed printing is a printing technique where individual sheets of paper are fed into the press one at a time. Unlike web printing, which uses continuous rolls of paper, sheetfed printing offers greater precision and flexibility. This method is ideal for producing high-quality, detailed images and is known for its ability to handle a wide range of paper types and weights.

Traditional sheet-fed printing is synonymous with the highest quality of lithography. Solo Printing’s new 10 color and 6 color Komori GL presses offer the latest in LED UV printing technology to deliver unsurpassed quality and turn times. Our presses reproduce images beautifully in a variety of formats and a wide selection of paper stocks on 60lb text weight to a maximum of 24pt.

Advantages of Sheetfed Printing:

- High Quality: Sheetfed presses produce sharp, vibrant images with excellent color accuracy and detail.

- Versatility: Capable of printing on various paper stocks, including thick, coated, and specialty papers.

- Precision Automation: Ideal for short to medium print runs where quality and detail are paramount. The automation aspect of sheet-fed printing allows the efficiency of operations to go up, while the cost goes down.

- Flexibility: Suitable for a wide range of products, from brochures and flyers to high-end magazines and packaging. Today, sheet-fed printing offers a higher degree of flexibility than it ever did before.

- Speed: Printing can execute up to 15,000 impressions per hour

- Specialty Finishes: Our sheet-fed presses have the ability to create just about any finish you can imagine. Some are:

• Varnish – Gloss, Dull and Matte

• Aqueous – and Overall Gloss, Matte, Dull and Soft-Touch

• UV – Spot and Overall Gloss, Matte, Dull, Textured and Glitter

Best Products for Sheetfed Printing:

- Marketing Materials: Brochures, flyers, and posters benefit from the high-quality output and versatility of sheetfed printing.

- Publications: Magazines, catalogs, and books, where vibrant images and precise text are crucial.

- Packaging: Premium packaging materials, such as boxes and labels, that require sharp, detailed graphics.

- Business Collateral: Business cards, stationery, and presentation folders that need to make a strong impression.

Sustainable Printing

The presses are equipped with LED, UV and IR curing technology. Apart from being efficient, these new additions also boast a greener way of printing as a result of Komori’s many environmental initiatives that fall in line with our values of being a reduced waste and greener commercial printing company. Click here to see more.

Applications

Sheet-fed printing can be used for a number of different applications. Our state-of-the-art equipment ensures there is no compromise regarding the level of quality for all types of products. This includes small to mid-sized brochure, booklets, catalogs, postcards, packaging, high-quality advertising, calendars, magazines and much more.

The Role of a Sheetfed Operator

Sheetfed operators are the backbone of any printing operation. They are responsible for running sheetfed presses, which are machines that print on individual sheets of paper. This contrasts with web presses, which print on continuous rolls of paper. Sheetfed presses offer exceptional quality and versatility, making them ideal for high-end printing jobs, such as marketing materials, brochures, and magazines.

Why Sheetfed Operators Are Vital

The precision and skill of our sheetfed operators directly impact the quality of the final product. Their ability to maintain consistency, troubleshoot issues, and make adjustments on the fly ensures that our clients receive the best possible printed materials. Without their expertise, the intricate details and vibrant colors that define our high-quality prints would not be possible.

Key Responsibilities of a Sheetfed Operator:

Setup and Calibration: Preparing the press for each job, ensuring that the correct inks, paper, and plates are used.

Quality Control: Continuously monitoring the output to ensure that each print meets the highest quality standards.

Maintenance: Regularly maintaining the press to prevent breakdowns and ensure optimal performance.

Troubleshooting: Quickly addressing any issues that arise during the printing process to minimize downtime and waste.

Training for Excellence

At Solo Printing, our sheetfed operators undergo extensive training to master the art of creating the perfect print product. This includes specialized training on our state-of-the-art Komori 10-unit sheetfed press. The Komori press is a powerhouse in the printing industry, known for its precision, speed, and versatility. It can handle complex print jobs with multiple colors and finishes, ensuring that every project meets our exacting standards.

Operators are trained to understand every aspect of the Komori press, from setup and calibration to maintenance and troubleshooting. This comprehensive training ensures that they can produce the highest quality prints while maintaining efficiency and minimizing waste. The expertise required to operate such advanced machinery highlights the skill and dedication of our sheetfed operators.

The precision and skill of our sheetfed operators directly impact the quality of the final product. Their ability to maintain consistency, troubleshoot issues, and make adjustments on the fly ensures that our clients receive the best possible printed materials. Without their expertise, the intricate details and vibrant colors that define our high-quality prints would not be possible.

Employee Spotlight: Conrado Lara

This month, we proudly feature Conrado Lara, a Sheetfed Pressman who has been with Solo Printing since May 19, 2003. Conrado is more than just an exceptional pressman; he is a beloved member of our team known for his sense of humor and dedication.

Conrado’s journey with Solo Printing began over two decades ago, and his impact has been profound. He is renowned for his meticulous attention to detail and unwavering commitment to excellence. His colleagues often praise his ability to keep everyone’s spirits high with his jokes and cheerful demeanor, creating a positive and productive work environment.

Outside of work, Conrado enjoys a well-rounded life filled with relaxation and family time. He loves BBQing, a favorite pastime that allows him to unwind and connect with his loved ones. Spending time with his wife and daughter is a priority, reflecting the same devotion he brings to his professional life.

Conrado’s story is one of dedication and expertise. His meticulous nature ensures that every print job he handles is of the highest quality, making him one of the best in his field. He embodies the values that Solo Printing holds dear: commitment, precision, and a passion for excellence.

In celebrating Conrado Lara, we celebrate all our sheetfed operators who bring their best to work every day. Their role is vital to our success, and their dedication is what makes Solo Printing a trusted name in the industry.

At Solo Printing, we take pride in our team of skilled professionals who ensure that every project meets our high standards. Conrado Lara’s story is a shining example of the expertise and dedication that drives our company forward. Here’s to Conrado and all our sheetfed operators—thank you for your hard work and unwavering commitment to excellence!