“This will increase Solo’s output capacity, while providing the added security of redundant production systems for future growth opportunities.”

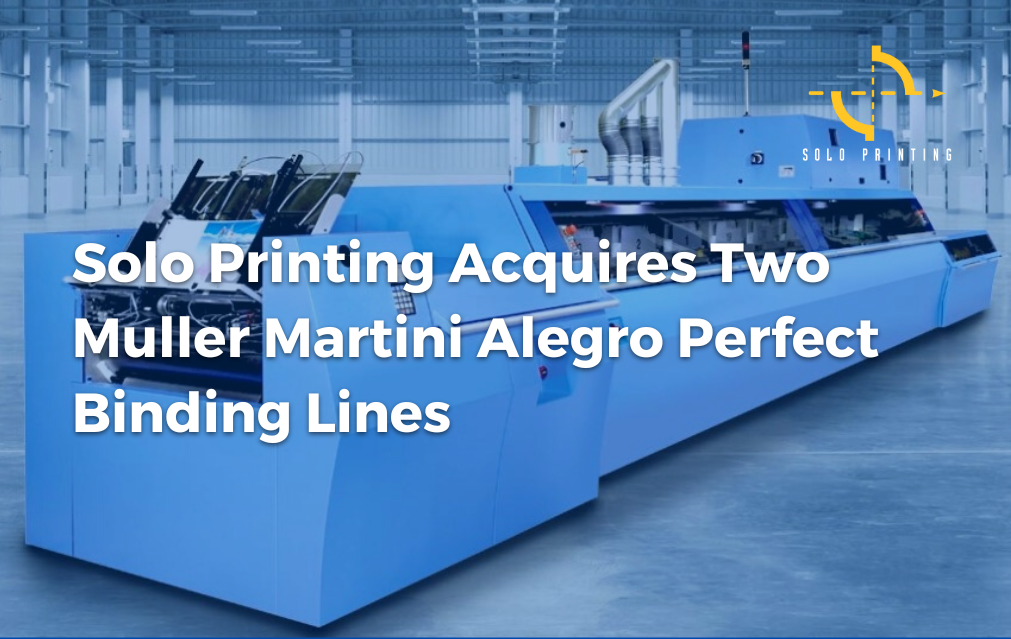

We are so excited for 2023 and our new acquisition of not only one but two Muller Martini Alegro perfect binding lines! We continue to make investments to better our company and our offerings to our clients. Because at the end of the day, our customers deserve a provider that strives to be the best it can be.

As one of the largest minority-owned businesses in the country and a supplier of exceptional color lithography, Solo Printing serves businesses around the nation as well as those in the Caribbean. Our extensive inventory of equipment has allowed us to specialize in a variety of goods, including booklets, brochures, and direct mail, and we are well positioned to satisfy your printing demands. Our equipment ranges from cutting-edge prepress, mailing and fulfillment, to the best web and sheet-fed printing.

By the end of 2023, Solo Printing will start using two Muller Martini Alegro perfect binding lines, our most recent capital purchases. In addition to boosting Solo’s output capacity, this acquisition of not just one but two Muller Martini Alegro perfect binding lines adds the security of redundant production systems for potential future development.

These new binding lines, which can bind 7,000 books per hour and have fully automated servo-controlled functionality and the best quality-control tools, will take the place of an old one. Moreover, one of the lines has PUR binding capabilities, including vision control to guarantee consistent and high-quality glue.

“It is an honor to continue to partner with a company like Solo Printing, which has a similar family-backed heritage as Muller Martini, and help them stabilize their operation with these lines that follow our Smart Factory and Finishing 4.0 design ideology.”

Andy Fetherman, President and CEO of Muller Martini Corp

Getting to Know Us

Solo Printing has dedicated over 38 years to providing businesses all around the nation with commercial printing solutions and we do that by investing in highly trained staff members and top-quality equipment.

Today, we are proud to produce brochures, catalogs, mailers and publications—along with a full range of general commercial printing products—in a 180,000-square-foot facility. We now have over 150 highly trained, dedicated employees.

As a significant supplier to many of the Fortune 500 and Fortune 1000 firms in the country, Solo keeps investing in cutting-edge technology to assist them fulfill the expanding needs of its clients.

“When it comes to equipment purchases, we only partner with the top companies in the industry, which is why we have partnered with Muller Martini for over 30 years. Muller’s continued innovation in equipment support services are second to none in the print industry. They are a vital part to our continued success” says VP of Sales, Robert Hernandez.

Our expanding position in sectors like healthcare, retail, hotels, and financial institutions is thanks in large part to Solo’s reputation as a forward-thinking supplier of print and print services.

How This Benefit Our Facility, Our Production, and Our Clients

Because of its cutting-edge drive and control technologies, the Alegro ideal binder satisfies the strict requirements in offset and digital printing in print runs of all sizes. The extremely adaptable machine architecture enables quick configuration changes for the successful management of nearly all production requirements, which can now vary as frequently as once per hour. In addition to ensuring incredibly fast processing times and incomparable production costs for books, separate drives, replicable order data, and integration options also provide greater space for future production.

Unbeatable Changeover Times

The Alegro stands out for its quick set-up times and record-breaking output rates because of its high level of automation. Each station is separately and directly operated. It is possible to duplicate the parameters, which directly affects the accuracy of the output and ensures exceptional book quality even for repeated works.

Wide Product Range

From ultra-small to A3, the Alegro can process a wide range of sizes. Two-up production is an option for A4 landscape products, which significantly lowers production costs across the board. The device is equipped to handle the demands of digital printing, or it is “digital ready.” It can manufacture books with manual changeovers and different thicknesses. The Alegro is compatible with all common binding techniques. It is feasible to use PUR, one-shot hotmelt, two-shot hotmelt, cold emulsion, and combination binding procedures.

Low Maintenance Costs

Shafts, gear boxes, or chains are not required to operate the stations thanks to the implementation of independent drives. As a result, less lubrication and maintenance are required.

Use in Digital Printing

The Connex data and process management system successfully establishes inline and offline interfaces to the printing systems. The Alegro ideal binder is being used more frequently in this industry thanks to ongoing improvements in inkjet digital printing manufacturing. The Alegro ideal binder is well-suited for the task because it is intelligent and entirely networked.

****

With over three decades of experience, Solo Printing has offered customized solutions to fit company marketing needs, whether that’s focusing on expansion, conversion, brand awareness, or building relationships.

Interested in working with us? Request a quote today.