Die cutting and custom printing services have been identified as critical drivers of direct mail marketing by top marketers. Die-cut shapes are attention grabbing and help to enhance direct mail campaigns because they improve lasting impressions. Physical Print ads require 21% less cognitive effort to read, process, and remember than digital ads. (R.C. Brayshaw, 2020) When you add in extra detail, print mail becomes even easier to digest and have cognitive recall for the brand.

The greatest marketing materials should attract prospects’ attention as soon as they open their mailboxes. When recipients receive a large number of letters on the daily, they typically swiftly examine them to determine what is significant and what is not. Letters from friends, bills, and businesses they know will typically take precedence.

What is Die-Cutting?

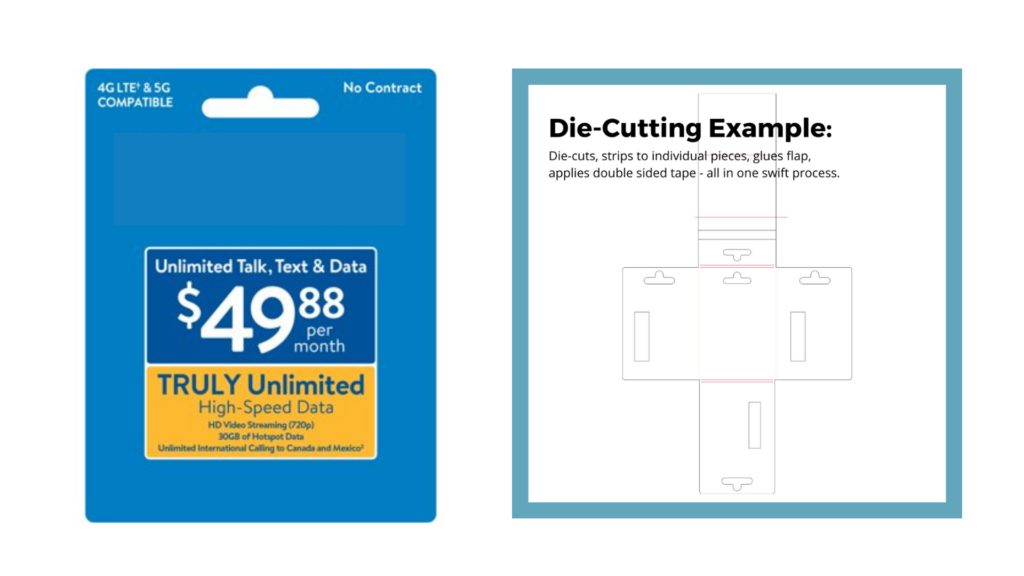

In its simplest terms, die-cutting uses a die to mass-produce cutout shapes that create unique, branded print pieces. Through this process, the same shape can be created repeatedly with the same dimensions each time. This process saves time and produces professional, consistent die-cut pieces with every run.

The dies used in the die-cutting process are metal-shaped objects that are capable of sharply cutting out shape designs. Think of a cookie-cutter! The metal shape of the die is what will create the shape of your final print piece.

Dies can come in a variety of different sizes and styles. Metal dies can be basic shapes, words, delicate designs, animals, flowers, or food shapes… you name it!

Die-cutting machines have a ton of awesome capabilities. They can cut shapes out of a variety of different mediums such as paper, chipboard, and even fabric!

Solo Printing’s professional rotary die-cutting services offer the consistency to make your project and your business stand out. You pick the cut design and medium type, and we’ll bring your idea to life!

The History of Die-Cutting

Die-Cutting was originally created for the shoemaking industry in the mid-1800s. Its main purpose was to cut leather, fabric, and rubber. During that period, the soles of shoes were cut by hand in a difficult, time-consuming, and expensive process.

Die-cutting was seemingly invented to cut out the very labor-intensive process of shoe-making. With die-cutting, shoe-makers were then able to create different shapes and sizes with ease.

Throughout many years, this process was implemented by the print industry. Print operators began using machines such as flatbed or rotary presses to create specialized shapes. In the modern-day, businesses everywhere now seek to create marketing collateral that will help them stand out and leave lasting impressions.

Solo Printing understands the importance and benefits of die-cutting for our customers. This is why we invested in a top-of-the-class, highly-efficient rotary die-cutting machine. Die-cutting and gluing have become a crucial segment of our full-service bindery department.

A Variety of Products

Add some flair to your usual print piece with die-cutting! When creating marketing collateral for your business, you want to make sure you capture the eye of your consumer.

Rotary die-cutting machines are capable of strategically cutting the corners and the inside of a print piece in order to create the desired shape effect. Our Bograma BS Rotary 550 Servo Die-Cutter has a Folding and Gluing System. With our new rotary die cutter, the capabilities and intricacy of die cut and folded pieces are endless, even for the most complex shapes and dies. Our machines have the ability to die-cut shapes, strip, fold and glue all in one pass.

Some of the die-cut products that Solo can create include:

- Door hangers

- Specialty Tags and Labels

- Pocket Folders

- Bottleneckers

- Mailers

- Postcards

- Signs

- Folded Boxes

- Packaging Materials

Distinctive Designs

One of the most important things about a business is its brand identity. Your logos and designs are special and distinctive to you. With Solo Printing, you can make sure they look their best with eye-catching die-cut designs that will enhance your print project. Die-cutting can create a three-dimensional effect for pieces that pop. Your brand name, logo, or promotional material will stand out from the competition using die-cutting.

A Finishing Touch

Adding unique finishing touches can also help entice buyers and establish a strong brand presence in the market. An excellent design can make your promotional materials more appealing and eye-catching, however, if you really want them to stand out to your prospect recipients, you should consider the various print finishing processes available.

The #SoloPrinting sheet-fed presses have the ability to create just about any finish you can imagine. Our #komori sheet-fed printers use the latest in UV technology, meaning we can even create spot gloss, textured, or glitter finish! Fill out the form below to contact us and learn more.

Below we will go into a little more detail about finishes you can add to your design.

Soft Touch: This type of coating creates a finish that gives the paper a velvety, soft texture.

Varnish: This is a clear ink that coats the entire print piece – adding shine and vibrancy, especially to photographs and images. It comes in three different finishes: gloss, satin, and matte. It works great for covers, flyers, and brochures.

Aqueous: This is a transparent, water-based coating that dries quickly. Its purpose is to protect printed pieces. The water-based feature makes it the most eco-friendly coating. Aqueous finishes include gloss, satin, matte, dull and soft touch.

UV: This is a clear, shiny coating applied to the stock that offers an elegant, luxurious feel for your print piece. You can choose Spot UV, which is applied only to select areas of your print piece. Or, other UV options which include gloss, matte, dull, textured and glitter.

Solo Printing also offers lamination, foil stamping, embossing, wire-O, and plastic coil binding.

State-of-the-Art Machinery

As with all of its printing services, Solo Printing uses state-of-the-art machinery to ensure that customers always receive the best quality product.

Our fully automated bindery equipment allows us to handle just about any job or campaign you aspire to create. From cutting and folding to stitching and perfect binding, all services are handled under one roof to ensure efficiency and highest quality possible.

From pocket folders to door hangers, Solo Printing can give your print job an edge with die-cut designs. Contact the team at 800-325-0118 or visit Solo Printing’s website to learn how our print professionals can meet all of your die-cutting needs.